Colloidal Silica as a Foundation for 3-D Printed Replacement Tissues

Researchers have made considerable headway in developing colloidal silica-based “bio-inks”

These “bio-inks” could provide a foundation for 3-D printed replacement tissues.

Better building blocks for tissue engineers

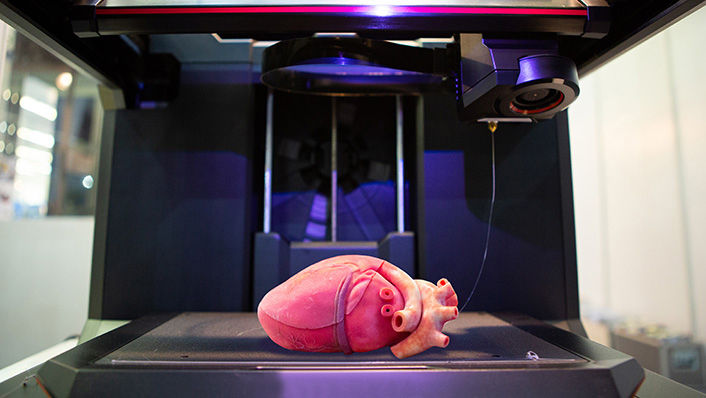

Equipped with a 3-D printer and the right design, you can print a toy, tool, or machine component. But how about a body part? Made-to-order organs are still many years away, but Marcy Zenobi-Wong and colleagues at the Swiss Federal Institute of Technology (ETH), Zurich, have made considerable headway in developing colloidal silica–based “bio-inks” that could provide a foundation for 3-D printed replacement tissues.

Standard 3-D printing processes involve the stepwise addition of layers of polymer in precisely defined patterns, using technologies that are now fairly commonplace. But biological applications create additional challenges. First, the polymer in the ink must be safe to both the cells being cultured for the tissue replacement and to the patient who will receive the graft. The bio-ink should also be capable of achieving different levels of flexibility or rigidity to mirror the physical properties of the destination tissue, be it skin or bone.

Proof-of-concept study

In an initial proof-of-concept study from 2018, Zenobi-Wong’s team focused on producing hydrogels that could serve as a bio-ink.1 The researchers formed hydrogels by coupling LUDOX® colloidal silica nanoparticles together with naturally occurring polysaccharides: alginate and gellan gum. In the study, these gels exhibited excellent printability and supported the survival and growth of mammalian cells. “This became exciting, because by adding the nanoparticles, you gain so much more functionality relative to conventional polymer-only inks,” Zenobi-Wong says. “It opened up a completely new field of possibilities.”

This became exciting, because by adding the nanoparticles, you gain so much more functionality relative to conventional polymer-only inks. It opened up a completely new field of possibilities.

Swiss Federal Institute of Technology (ETH), Zürich

Demonstrating adaptability

In 2019, her group demonstrated some of those possibilities by making chemical modifications to the silica nanoparticles that enabled the nanoparticles to form covalent linkages with the surrounding polysaccharide strands.2 These bonds are far stronger than the electrostatic interactions that held together the first-generation ink. But the bonds are also reversible, which allowed the researchers to dynamically control how extensively the hydrogel is cross-linked by manipulating its chemical environment. “This means you have a material that can adapt—it’s not just a static straitjacket,” Zenobi-Wong says.

These covalently linked gels showed improved stability and let the researchers precisely print sophisticated shapes such as a hydrogel “ear.” The new formulation also allowed them to reduce the amount of silica nanoparticles relative to their initial study, which could prove advantageous in clinical applications, in which a goal is to introduce into patients as little foreign material as possible. Zenobi-Wong’s team also implanted these printed scaffolds under the skin of live mice and observed good evidence of biocompatibility.

Importantly, her group showed that they could successfully print these gels as a mixture with living cells, producing 3-D hydrogel structures with cartilage-forming chondrocytes embedded within. Both human- and cow-derived cells flourished in 28 days of being cultured within the printed structure.

Bio-ink recipe advances

Zenobi-Wong continues to refine her bio-ink recipes to achieve greater control over the structure and properties of printed products; she thinks that the polysaccharide and silica nanoparticle formulation could offer an appealing option for printing a variety of tissues. For example, she says researchers could use nanoparticles to anchor specialized growth factor proteins that selectively promote the proliferation and physiological function of different cell types. Zenobi-Wong thinks this approach offers the opportunity to simultaneously optimize the structure of a printed implant while tuning it biologically to ensure that the embedded cells can flourish. “This might be an approach where you can do something in an easy way with these particles that you couldn't do otherwise,” she says.

A global leader in specialty chemicals

Cited in over 35,000 patents, applications for LUDOX® colloidal silicas are numerous and diverse. Researchers continue to discover new ways to use LUDOX® colloidal silicas in cutting-edge research, breaking ground for future scientific innovation and leading to potentially thousands more patents to come.

Featured

General Industrial

Grace's expertise in applying innovative technologies to base materials such as silica and alumina transform them into functional ingredients such as silica gels, silica sols, precipitated silica, zeolitic molecular sieves, and modified silica products that impart a range of beneficial properties to industrial products.

LUDOX®

LUDOX® colloidal silicas are discrete nanoscale spherical particles of amorphous silica dispersed in water.

-

1. Mihyun Lee et al., “Exploitation of Cationic Silica Nanoparticles for Bioprinting of Large-Scale Constructs with High Printing Fidelity,” ACS Appl. Mater. Interfaces 10, no. 44 (Nov. 7, 2018): 37820–28, https://doi.org/10.1021/acsami.8b13166.

2. Mihyun Lee et al., “Nanocomposite Bioink Exploits Dynamic Covalent Bonds between Nanoparticles and Polysaccharides for Precision Bioprinting,” Biofabrication 12, no. 2 (March 13, 2020): 025025, https://doi.org/10.1088/1758-5090/ab782d.