Demand for High-octane Gasoline Drives Alkylate Values

ACHIEVE® 400 catalyst technology sets the bar for butylene selectivity

In the U.S., where transportation fuel-based refineries remain dominant over petrochemical integrated refineries, the regulatory landscape has driven the value and importance of alkylate in the refinery higher than ever. Alkylate has always been an important blending component in refinery gasoline pools given its excellent qualities: high octane, low sulfur, zero aromatics, and low RVP. However, the more severe hydroprocessing required for meeting Tier 3 low sulfur gasoline limits meant significant octane destruction within refinery gasoline pools. Not only were refiners challenged to offset this octane destruction, the ongoing transition to more fuel-efficient engines (e.g. via CAFE standards which govern how far vehicles should travel on a gallon of fuel) increased demand for Premium grade, higher octane gasoline. In anticipation of this increasing demand for octane, U.S. refineries added over 100 MBPD of alkylation capacity from 2017 to 2021.

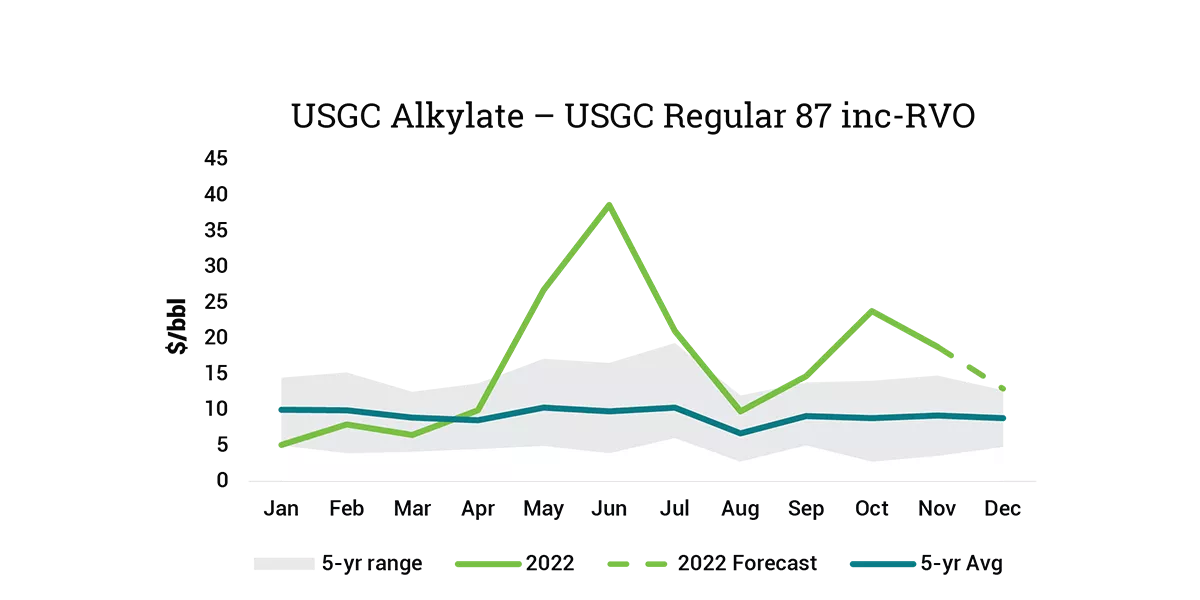

More recently, a combination of favorable distillate economics and IMO regulations governing sulfur in marine fuels have given refiners an incentive to pursue vacuum gas oil (VGO) conversion in hydrocracking units and/or direct blending into the low sulfur fuel oil (LSFO) pool instead of conversion at fluid catalytic cracking (FCC) units. That ultimately reduces high-octane FCC naphtha in the gasoline pool. This has pushed alkylate values to the high end of the 5-year range and at times substantially above, giving refiners an opportunity.

Most refiners consider FCC butylene to be the most favorable feedstock for high-value alkylate production. The current market dynamics have made butylene the most valuable product for many refiners operating FCC units. Since 2013, our workhorse ACHIEVE® 400 family of FCC catalysts, which is widely recognized for its industry-leading butylene selectivity, has helped refiners boost alkylate production. ACHIEVE® 400 catalyst technology is a high-performance catalyst solution with tailored acidity and multiple differentiated technology components that can help deliver an optimum level of butylene to keep the alkylation unit full and maintain refinery pool octane. Since its initial commercialization, Grace has continued to advance the technology with innovations such as ACHIEVE® 400 Gold catalyst and ACHIEVE® 400 Prime catalyst. These catalysts deliver incrementally higher butylene yields and higher gasoline octane. In one of many cases of success in the field, ACHIEVE® 400 Prime catalyst delivered $1.10/bbl in value over competitive butylene-selective catalyst technologies.

Finding reliable solutions to improve butylene selectivity should be a top priority for many North American refineries in the near term. Find out more about how our catalyst technology can help refiners maximize the most valuable products from the most flexible unit in the refinery – the FCC. We are continuing to invest in research to develop step-out innovations for future generations of ACHIEVE® 400 catalysts. Ask us more about what’s next in refining technology innovation.