Insights from the 2025 ACI Future of Chemical Recycling Conference

The 2025 Future of Chemical Recycling Conference, presented by ACI, provided a wealth of knowledge and insights into the evolving landscape of chemical recycling. The conference highlighted the need for strong regulatory frameworks and investment, plus continuous innovation to propel the industry forward. By addressing these challenges and embracing technological advancements, we can pave the way for a more effective and efficient chemical recycling sector with expanded solutions for recycling plastic. Here are some key takeaways from the event.

Navigating Hurdles: The Path to Growth

Europe’s Plastic Packaging & Waste Regulation provides the impetus for European producers to incorporate recycled content in various types of packaging by 2030. As a result, the chemical recycling market is poised for significant growth, with predictions indicating that 2-3 million tons of plastic will be processed through advanced recycling (AR) by 2030. However, the market faces several regulatory and logistical challenges. The lack of regulatory clarity, particularly on mass balance, remains a major issue. The EU's potential adoption of the fuels exempt approach could limit claims and reduce the attractiveness of first-generation recycling technologies. Additionally, the energy intensity of current processes, bureaucratic hurdles, and inconsistent rules for transporting pyrolysis oil (PyOil) across borders further complicate the market landscape.

Challenges in Chemical Recycling

The chemical recycling industry is still in its infancy and requires substantial funding and incentives to gain traction. The current regulatory framework does not support a strong business case, and traditional project management views are hindering the industry's potential. Companies are grappling with the cost of recycled materials, regulatory restrictions on food contact applications, and inefficient processing methods. There is also a mismatch between the cost/quality ratio that consumers use to make product choices and the higher costs of recycled materials.

Technological Innovation

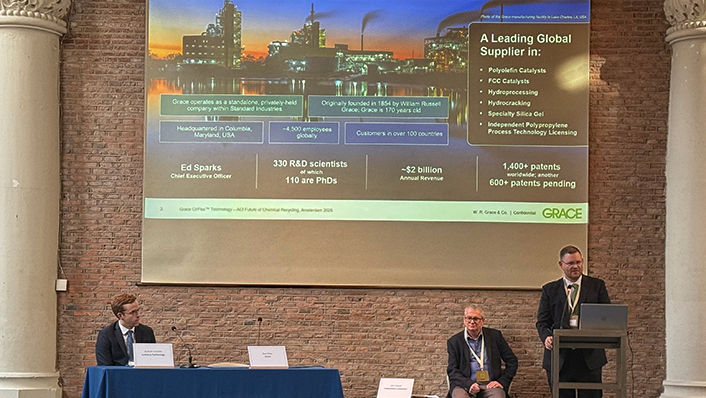

Technological advancements are crucial for addressing the inefficiencies in many first-generation solutions. Innovations such as continuous microwave-assisted pyrolysis for small-scale operations; large-scale thermal PyOil production; and catalytic chemical options are making significant strides. Technologies like Grace’s CirFlex™ technology, a catalytic chemical conversion process, are well-positioned for their potential to address the shortcomings of first-generation processes with lower emissions, better resouce utilization, and better economics.

Advancing A Potential Solution

Continuous innovation is propelling the industry toward a viable solution to chemical recycling. It was exciting to hear the conversation and see the innovation at work during the Future of Chemical Recycling Conference.

As Brian Kimberley, VP of Marketing, Licensing and Services, aptly states, “The future of chemical recycling lies in our ability to continuously innovate and adapt. Through our CirFlex™ technology we are driving change and working to make a positive impact on the environment. It’s exciting to be part of a potentially game-changing solution and to consider the possibilities of the future.”