Drive efficiency and cost savings in white masterbatches

Titanium dioxide extenders are a preferred choice for opacification for two main reasons: first, the peak of the light scattering power of a pigment is at half the wavelength of light (500nm); second, the higher the refractive index of the material, the better the light scattering or refraction.

If titanium dioxide particles are too close together, they overlap. This crowding reduces the number of possible light-scattering sites, hence reducing opacity. To reduce crowding, manufacturers need to use smaller fillers or extenders. These materials can separate the TiO2 particles more effectively, giving way to spacing.

Deliver enhanced TiO2 extender performance

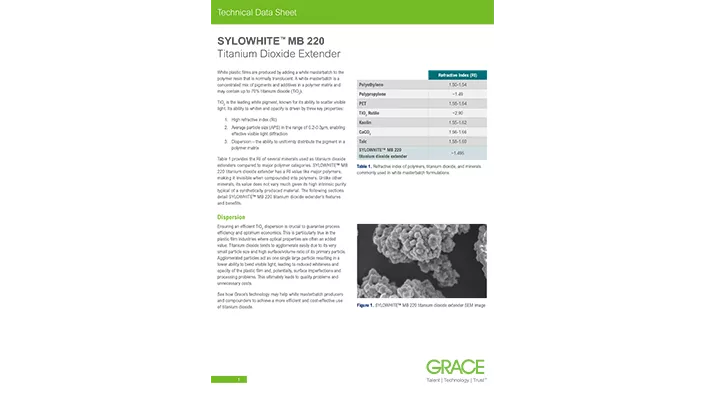

SYLOWHITE™ MB 220 titanium dioxide extender (TiO2) is an amorphous synthetic product designed to deliver enhanced TiO2 extender performance in plastic applications. Its intrinsic chemical purity and optical properties (high L value and low b value) help to reduce the amount of TiO2 required. This is crucial for process efficiency and optimum economics.

SYLOWHITE™ MB 220 silica has a unique ability to scatter visible light allowing masterbatch producers and compounders to whiten and opacify plastic films. The product’s ability to achieve these properties is driven by:

- High refractive index (RI)

- Average particle size (APS) enabling effective visible light diffraction

- Dispersion – the ability to uniformly distribute the pigment in a polymer matrix

SYLOWHITE™ Technical Data Sheet

Download the technical data sheet to learn more about the capabilities of SYLOWHITE™ TiO2.

The data sheet details:

- Dispersion benefits

- SYLOWHITE™ silica performance compared to competitive products

- Case study highlighting customer cost savings